GENERAL

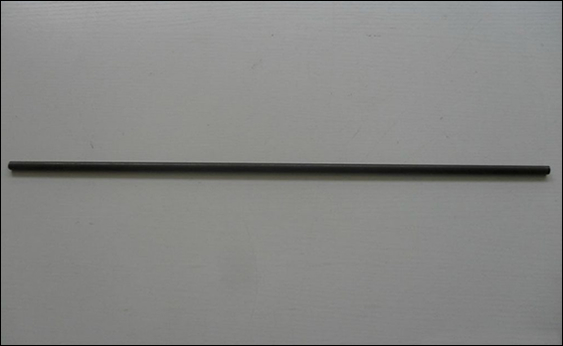

Plain pc wire refers to steel wire for prestressed concrete with smooth surface treatment, without ribs / groove, not indented.

Materials: Carbon steel

Plain PC Wire Dia: 4 / 4.5 / 4.8 / 5 / 6 / 6.25 / 7 / 8 / 9 / 10mm

Features:

1. Low relaxation high tensile strength

2. Material: 82b / 77b

3. Standard : BS5896 GB/T5223-2002 ASTM A421 ASTM A881/A881M

4. Tensile strength:1570Mpa 1670Mpa 1770Mpa 1860Mpa

5. Surface: smooth

6. Coil weight: 0.8 to 1.5T

Common Specifications:

| Nominal diameter (mm) |

Tolerance (mm) |

Tensile strength No less than (MPa) |

Off-proportion extension stress no less than (kN) |

Elongation no less than L0=200mm (%) |

Bending test | Relaxation value 1000h no more than | ||

| Times/ 180° No less than |

radius (mm) |

Ⅰ | Ⅱ | |||||

| 5.00 | ±0.05 | 1470 1570 1670 1770 |

1250 1330 1410 1500 |

4 | 4 | 15 | 8 | 2.5 |

6.00 |

±0.05 | 1570 1670 |

1330 1420 |

4 | 4 | 15 | 8 | 2.5 |

| 7.00 | ±0.05 | 1470 1570 |

1250 1330 |

4 | 4 | 20 | 8 | 2.5 |

Material: High carbon steel

| Nominal Dia. (dn/mm) |

Tolerance (mm) |

Tensile Strength σb/MPa Not less than |

Yield Strength (σp0.2/Mpa) Not less than |

Elongation at max load (Lo=200mm) δgt/% Not less than |

Bending Times (180°) Not less than |

Bending Radius R/mm | Relaxation Properties |

| The relaxation at 1000 h, Initial load to 70% of nominal tensile strength (r/%) Not more than |

|||||||

| 4.8 | ±0.05 | 1470 1570 1670 1770 1860 |

1290 1380 1470 1560 1640 |

3.5 | 4 | 15 | 2.5 |

| 5.0 | |||||||

| 6.0 | ±0.05 | 1470 1570 1670 1770 |

1290 1380 1470 1560 |

4 | 15 | ||

| 7.0 | 20 | ||||||

| 8.0 | ±0.06 | 1470 1570 |

1290 1380 |

4 | 20 | ||

| 9.0 | 25 |

SPECIFIC PRODUCTS

Plain Steel Wire (Steel Core), Plain Carbon, Size 6.0mm

Diameter 6.0 mm (5.7–0.06mm)

Wires exported to Karachi,

PAKISTAN

PC Steel Wire 1570 Mpa, Plain Surface 6mm Smooth Wire

Plain pc wire dia 3/8(9.53mm) and 7/16(11.11mm) also exported to

Pakistan.

High Tensile Plain PC wire, 5.0mm

Standard: Prestressed concrete wire astm a-421, a-881 and nmx b-293 5.00mm

| Parameters | Value | Value |

| Diameter, mm | 5.0mm | 5.50MM |

| Tolerance, mm | +_0.04 | +_0.04 |

| Minimum Breaking Load , Kg/mm2 | 175 | 172.5 |

| Elastic Limit, Kg/332 | 148 | 146 |

| Min Elongation, % | 4.00 | 4.00 |

| Area, mm2 | 19.63 | 23.95 |

| Linear Weight, gr/m | 154.10 | 188.00 |

| Linear Yield, m/ton | 6,489 | 5,497 |

| Coil ID, mm | 1830 | 1830 |

| Coil weight, Kgs | 1000 | 1000 |

| Surface Finish | Plain & Smooth | Plain & Smooth |

Packing details : Sea worthy good quality export Palletized packing

High Tensile Plain PC wire, 5.0mm, wires exported to India

HIGH TENSILE STEEL PRESTRESS CONCRETE WIRE DIAMETER 7 MM

Bright plain high tensile steel wire of 7mm diameter as Specified below:

PC wire - BRIGHT PLAIN WIRE

Wires exported to AMMAN – JORDAN

| Se. # | Specification Description |

| 1 | Steel required has to be bright plain - high tensile steel wire 7mm diameter and will be used in manufacturing prestressed concrete poles for medium voltage networks. |

| 2 | The steel should conform in all respects with the requirements of the latest edition of B.S. 5896 or Chinese specifications [presteressed wire 7.00-1570-WLR-P-GB/T 5223/2002] or equivalent. |

| 3 | The nominal tensile strength of the steel should be (1570 N/mm2). |

| 4 | The steel should be of "Low relaxation " quality, and the wire is pre-straightened and will run out straight form the coil when used at site. |

| 5 | No joint is allowed in the wire which should be one piece in the coil. |

| 6 | Steel should be supplied in large diameter coils of 1.8 - 2.4 m. |

| 7 | The weight of Each coil should be approximately 1000 Kgs. |

| 8 | Good attention should be paid to the packing of each coil to ensure good protection to the steel during loading, shipping, unloading, transportation, and storing at the site of the purchaser. For that, every coil should be tightly wrapped by proper and secure seaworthy packing. |

| 9 | Each coil should have a separate label made of steel sheet with a

reasonable size. This label should contain the following information: 1. EDCO/FPO/...... (The number of the FPO will be given after awarding the inquiry). 2. Coil No:...... 3. Weight of coil |

| 10 | Mechanical and other relevant tests should be carried out on sufficient number of samples from the materials. Our engineer(s) will attend these tests in the laboratory of the manufacturer. Moreover; if the purchaser decided, he has the right of testing some samples in a 3rd party (for example SGS) laboratory at the manufacturer Expense. |