Kinwey offers Prestressed Concrete Wires (pc wire) in mainly two types: Mono pc wire and Multi-wire strand.

PC steel wires are widely used in concrete construction industry for pre-stressed steel structures: large-span bridges ( stay cable system), overhead crane beam, cement poles, coal mines rock-soil anchoring project, multi-storey frameworks (slab and hollow floors), subway, railway sleepers, dams, shell safety of nuclear power stations, high-rise buildings (television tower, water towers, concrete silo, sewage treatment, hydropower project, stadiums) and etc.

Quality: ASTM A-416, BS 5896, JIS G3536, the standards and cutomized specifications.

Common wire materials for production: High tensile wires, plain or galvanized.

The process involves the continuous heating and stretching of a cold drawn high-carbon steel wire to produce a finished product with a much improved yield stress and greatly reduced load relaxation.

PC Wire / Strand Classifications

Prestressing concrete steel wire can be divided according to wire diameter, the intensity level, the surface coating or cross-section:

1. According to diameter, PC steel wire can be categorized as: 4mm, 4.8mm, 5.0mm, 5.1mm, 6.0mm, 6.35mm, 7.0mm, 7.8mm, 8.0mm, 9.0mm, 10.0mm, 11mm, 12mm and so on.

2. According to tensile strength, pc wire can be classified as: 1470MPa, 1570MPa, 1670MPa, 1770MPa and 1860MPa.

3. According to the surface coating, pc wire can be classified as: uncoated prestressed steel wire, prestressed epoxy coated steel wire and galvanized prestressed steel wire.

4. According to forms of the surface, it can be classified as: Round plain wires, spiral ribbed (spiral ribbed or helix grooved) steel wires, crimped wires, slotted (indented) wires, and so on.

5. According to wire treatment process, pc wire can be categorized as follows: cold-drawn pc wire and low relaxation pc wire.

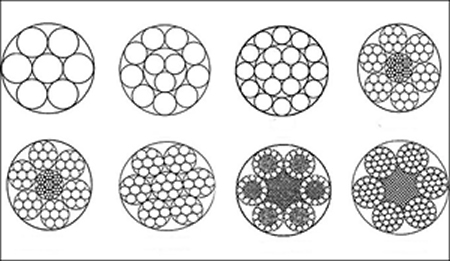

6. According to wires applied, pc wire can be classified as single individual pc wire and helically stranded wire ( pc strand).

7. According to applications, pc wire / strand can be divided into:

Un-bonded strand: zinc coated, grease filled; uv stabilized polymer sheath, for post tensioning

Bonded strand, retardant, galvanized bright, with PE shielding, for stable cable, suspension wire cable for bridge construction

8. According to structures, stranded wire can be classified into 2 wire strand, 3 wire strand or 7 wire strand mostly.

Prestressing steel wire / pc wire, functions differently compared with reinforcing steel (rebars):

Post-tensioning is very useful to defeat the natural weakness of concrete in tension and to optimize its strength in compression. In concrete structures, using high-tensile steel wire / strand placed in the element prior to casting will:

1,

Reduces occurrence of cracks .

2,

Increase in durability.

3,

Less deformations (improved serviceability).

4, Increase in shear capacity.

Since concrete is weak in tension, the reinforcing steel bar / rebar is used inside concrete for strengthening and reinforcing the tensile strength of concrete. Reinforcing steel bars are used to absorbs the tensile, shear, and sometimes the compressive stresses in a concrete structure.

Newly Exported Products

PC Wire, PC Strand Wire, PC Steel Wire For Vietnam,

PC Steel productions as below:

Comm : PC STEEL BAR/PC WIRE

Size: Φ7.1 , Φ9.0, Φ6 , Φ5

PC Wire 0.5" size for Bridge Project. in Lahore (Pakistan).

High Tensile Steel Wire (low Relaxation Prestressed Concrete Wire ) For Amman – Jordan

Bright plain high tensile steel wire of 7mm diameter as specified :

| 1 | Steel required has to be bright plain-high tensile steel wire7mm diameter and will be used in manufacturing prestressed concrete poles for medium voltage networks. |

| 2 | The steel should conform in all respects with the requirements of the latest edition of BS.5896 or Chinese specifications [prestressed wire 7.00-1570-WLR-P-GB/T5223/2002] or equivalent. |

| 3 | The nominal tensile strength of the steel should be (1570N/mm2). |

| 4 | The steel should be of Low relaxation “quality and the wire is pre-straightened and will run out straight form the coil when used at site. |

| 5 | No joint is allowed in the wire which should be one piece in the coil. |

| 6 | Steel shouldbesuppliedinlargediametercoilsof1.8 -2.4m. |

| 7 | The weight of Each coil should be approximately 1000Kgs. |

| 8 | The packing o f each coil ensures good protection to the steel during loading, shipping, unloading, transportation, and storing at the site of the purchaser. For that, every coil is tightly wrapped by proper and secure seaworthy packing. |

| 9 | Each coil has a separate label made of steel sheet with a reason able size. |

| 10 | Mechanical and other relevant tests should be carried out on sufficient number of samples from the materials. Our engineer will operate these tests in the laboratory. The purchaser has the right of testing some samples in a 3rd party (for example SGS) laboratory at the manufacturer Expense. |

Uncoated 7 Wires PC Strands With Following Sizes ( ½ And 0.6 Inches ) For In Uae And Oman.

Grades : low relaxation according to ASTM- 416 , Grade 270 ( 1860 MPa).

7 Wire PC Strand, 15.24mm (ASTM A416 Gr 270 Low Relaxation) , 2.0ton – 3.5tons per coil

PC indentened Wire for Damascus

Straightened indented cold drawn pre-stressed steel wires of nominal diameter 7 mm.

according to the EN 10138/4/979 or BS 5896/80

- Nominal tensile strength: 1570 N/mm2

- Yield limit : 1420 N/mm2

- Guaranteed Yield point: at 0.2 % of permanent elongation 1380 N/mm2.

- Deflections : Max. 12 mm in 1 meter long.

- Diameter tolerance : 7 mm ± 0.05 mm

- Relaxation: Class 1 or Class 2

- Weight of Coil : manufacturer Choice , preferable less than 1000 Kg .

- Coil nominal inner diameter: 1800-2000 mm.

- Coil nominal outer diameter: about 2200 mm.

- Indentation depth: 0.15 mm± 0.05 mm , three indented faces with angle 45° , pitch 8 mm.

PC still wire for prestressed concrete railways sleepers, diameter 3 mm for Damascus

Specifications of the material (tensile strength; surface; coils weight, standard).

- Materiral : Prestressed concrete pc wire steel dia 7mm.

- Standard ACC BS 5896 – 1980 and EN 138/4/1979 OR equivalent

- Tensile strength :1570 N/mm2.

- proof strength :1420 N/ MM2.

- Diameter :7 mm.

- Relaxation :class1.

- deviation :max 12mm for L1m.

- the Surface:

indented pc wire steel.

indent depth 0.15 mm +- 0.5.

indented on three faces at a 45 degree angle.

- Coils weight: (500 , 700) kg.

- Interior diameter (1800-2000)mm

- Outer diameter of the coils approx. (2200 ) mm.

Standard:

all Production (pc wire), control and testing according to above standard.

- inspection :

will be by a neutral third party, through a competent inspection company selected by payer.

- Diameters :7 mm. - Tolerance of diameter 7mm +-0.5

- Quantity: 300 ton.

Delivery syria port( lattakia)

PC Plain Cold Drawn Wire 4 mm Diameter For Germany

PC wire strand 4mm

PC wire strand 5mm

Spiral Steel Wire-OD2.7mm for Malaysia

NTW Wire - Non Tensions Wire-OD6mm

Prestressed PC Wire- 4 side indented oval shave

Size: OD 5mm

OD 7mm

Supply Prestressing Steel Wire 140/160 Dia 9.4mm In Length 2337mm, Round Smooth, Cold Drawn Acc. To En10138-2

Material grade:smooth wire st1460/1620 min.

Size:dia.9.4mmx2337mm length

Galvanized Steel Strand

The vertical hot-dip galvanized technology ensures coating thickness.

Common structure: 7 strands / 19 strands

Application: for ACSR, stay wire, Guy wire, barrier cable, guardrail strand, overhead earth wire

Material: high carbon steel

Galvanized steel wire size: Φ1.44mm-4.770mm

Strand size:7×(1.44-4.2 mm);19×(1.44-3.5mm)

Tensile strength: different Grade from min.1470 N/mm2 to min.1960N/mm2

Zinc coating: According to ASTM A475 Class A

Meets ASTM Specifications A475 or A363 or ASTM B498 or BS EN 50189

PC Steel Wire S Grooved, Supply to Iran

| Name | pc steel wire |

| Designation | Diameter 4mm 4.8mm 5mm 6mm 7mm |

| Grade | ASTM A 421 |

| Nominal cross section area (mm2) | 18.7 |

| Diameter Tolerance | 0.00mm / ± 0.05mm |

| Yield stress (N/mm2) | 1400 Min. |

| Tensile stress (N/mm2) | 1670 Min. |

| Elongation (%) | 3.5 Min. |

| Relaxation (%) | 2.0 Max. |

| Groove number | 4 |

| Groove direction | S |

Cold Drawn PC Wire in Coils

Material: Prime Alloy Steel Wire for in coils for prestressing of concrete

Technical Specifications:

- Designation as per British Standard BS 5896/2 Wire-1670-7-DE-relax 2

Explanation of designation (Basic specifications)

- Standard BS 5896-section 2

- Diameter of Wire: 7 mm.

- Surface condition: smooth (E)

- Tensile strength: 1670 MPa

- Relaxation : class 2 (1% @ 60% initial load, 2.5% @ 70% initial load and 4.5% @ 80% initial load)

- Coil outer diameter: 2.3 m. max.

- Yield stress (0.1 proof Stress): 1390 MPa

- Elongation: 3.5%

- Ductility: 4 Times 20 mm. Bending

Packing: Mill's Standard with Coil Weight of 1700-2400 Kg.

Indented PC Wire, Steel

- Materiral :

Prestressed concrete pc wire steel dia 7mm.

- Standard ACC BS 5896 – 1980 and EN 138/4/1979 OR equivalent

- Tensile strength :1570 N/mm2.

- proof strength :1420 N/ MM2.

- Diameter :7 mm.

- Relaxation :class1.

- deviation :max 12mm for L1m.

-the Surface:

indented pc wire steel.

indent depth 0.15 mm +- 0.5.

indented on three faces at a 45 degree angle.

- Coils weight: (500 , 700) kg.

- Interior diameter (1800-2000)mm

- Outer diameter of the coils approx. (2200 ) mm .

- Diameters :7 mm. - Tolerance of diameter 7mm +-0.5

Delivery to Syria

PC Bars

Steel Bars for manufacturing of PC Poles and Spun Piles.